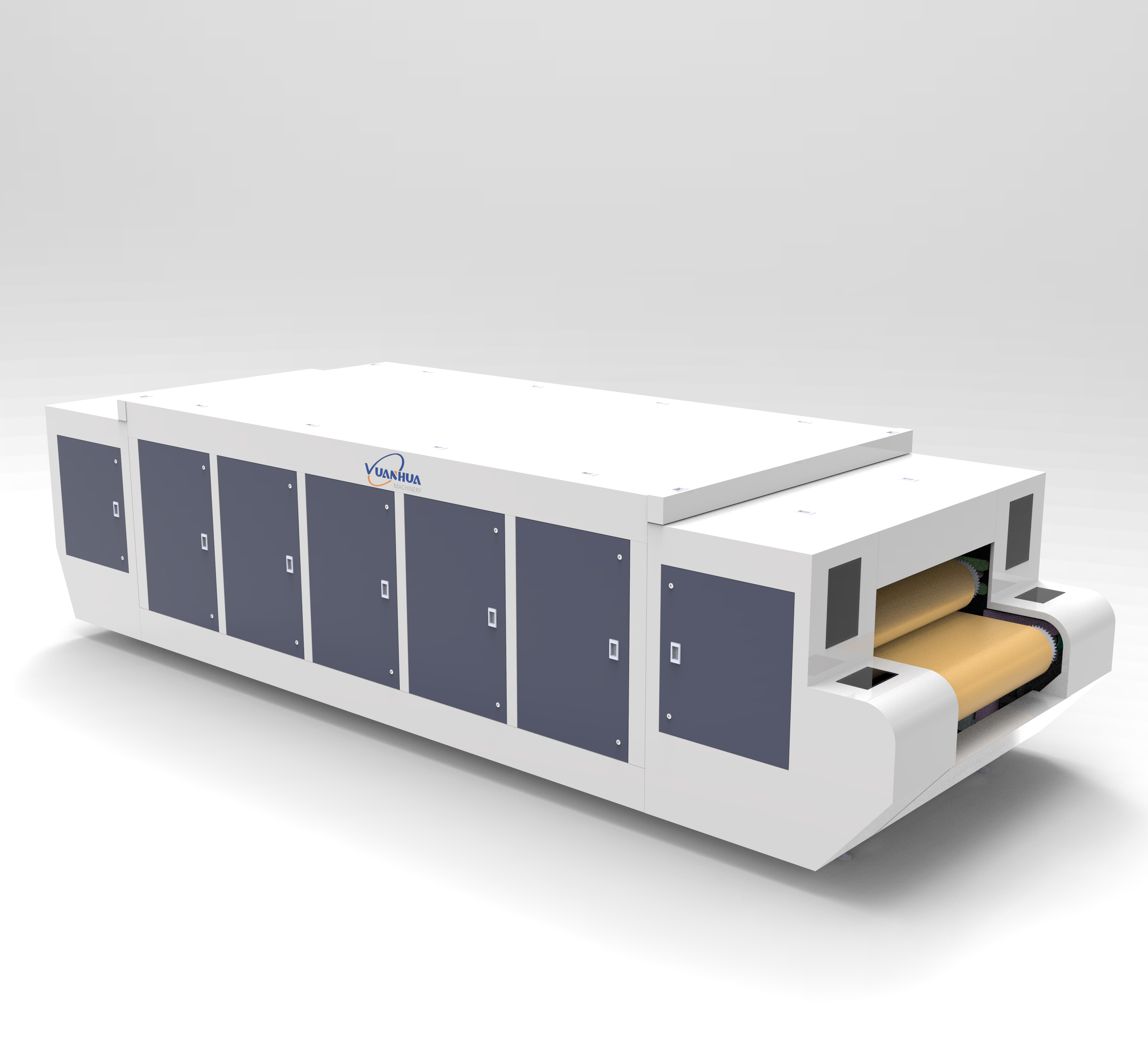

Flatbed (Double Belt) Laminating Machine

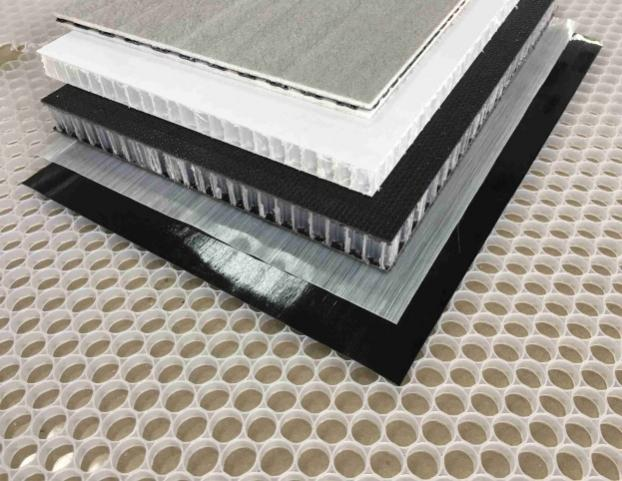

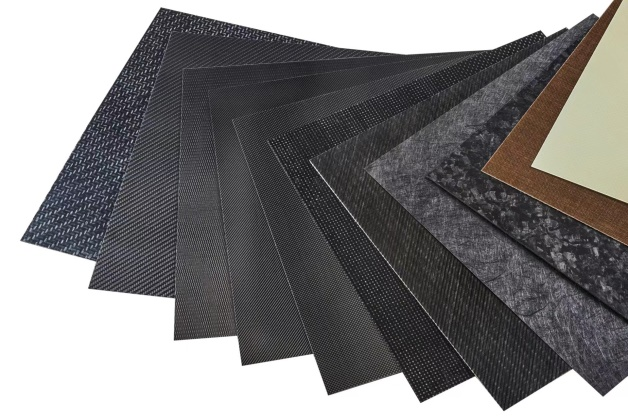

Flatbed laminating machine, also known as double belt laminating machine, is a machine that put two or more than two layers of the same or different materials together, such as fabric and fabric, fabric and paper, fabric and artificial leather and all kinds of plastic, with rubber sheet coil heating them to melt, semi-melt state or with a special adhesive composite as a whole. The composite material is heated evenly through two conveyor belts to transfer pressure and integrate a contact heating and cooling system. With sufficient heating and cooling zones, the material is perfectly compounded and has high composite strength. Through the gaps between the conveyor belts and precise height adjustment, even 150mm rigid plates can be compounded.

The machine is suitable for industrial textiles, automobile industry, clothing industry, filtering materials, medical treatment, new materials etc,.

Advantages:

1. It can glue and laminate different materials and multi-layer materials with high compound fastness, improve production efficiency and reduce production cost.

2. The heating elements are arranged flexibly, and the heating system can choose electric heating or oil heating. The edge zone of the whole heating system is divided into two groups, with the temperature range from 20°C to 250°C, which can be adjusted independently in all areas according to the needs of users, which can effectively save energy and reduce production costs.

3. The machine uses the net belt with automatic infrared deviation device, prevent the net belt deviation effectively, prolong the service life of the net belt.

4. According to the need to select DC motor or inverter linkage, so that the machine has a better control.